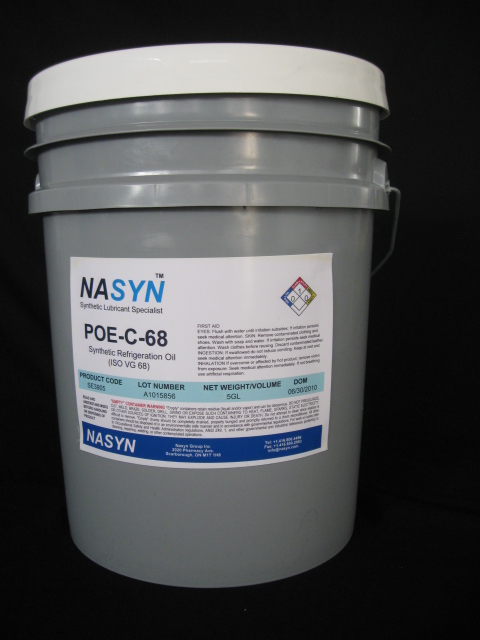

NASYN POE SERIES

APPLICATIONS:

|

Typical Applications |

|

|

Reciprocating |

√ |

|

Rotary Vane |

√ |

|

Scroll |

√ |

|

Centrifugal |

√ |

|

Screw |

√ |

TYPICAL PROPERTIES

|

|

POE-22 |

POE-32 |

POE-LT-32 |

POE-MA |

POE-46 |

POE-68 |

POE-100 |

POE-120 |

POE-150 |

POE-170 |

POE-220 |

|

Density 15.6℃, g/cc |

0.987 |

0.994 |

0.982 |

0.942 |

0.937 |

0.974 |

0.965 |

0.967 |

0.978 |

0.978 |

0.976 |

|

Visc @ 40℃ cSt |

22.55 |

31.96 |

29.15 |

31.96 |

50.5 |

64 |

100 |

124.9 |

150 |

175.2 |

215.9 |

|

Visc @ 100℃ cSt |

4.9 |

5.63 |

5.91 |

5.63 |

7 |

8.9 |

12.7 |

13.7 |

16.45 |

16.5 |

20.8 |

|

Viscosity Index |

149 |

106 |

153 |

106 |

94 |

114 |

120 |

106 |

101 |

93 |

113 |

|

Pour Point ℃ |

-54 |

-45 |

-52 |

-45 |

-45 |

-43 |

-36 |

-27 |

-27 |

-27 |

-25 |

|

Flash Point ℃ |

232 |

235 |

243 |

235 |

248 |

266 |

254 |

262 |

280 |

271 |

271 |

|

Fire Point ℃ |

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

318 |

|

TAN |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

Water Content ppm |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

<50 |

MOISTURE-PROOF SPECIAL PACKAGONG:

To be “hygroscopic” describes a lubricant's tendency to absorb moisture from air. Polyol esters are generally 10 times more hygroscopic than mineral oil and alkylbenzene.Polyol esters will absorb up to 0.2 % moisture or 2,000 PPM while mineral oils absorb up to 200 PPM. To ensure moisture is kept to a minimum, NASYN has a unique way of packaging the POE Series using a nitrogen purge which leaves a nitrogen blanket over the lubricant to help ensure it remains dry. Over a period of time moisture can migrate through plastic and the lubricant will pick it up. NASYN packages the POE Series in metal containers.

NASYN offers a complete product line of POE refrigeration lubricants. NASYN also has the capability of tailoring the viscosity to meet your specific application.